Wielandts UPMT is a technological company that develops unique machining and replication processes to provide custom solutions to the most demanding customer requests for optical and mechanical precision parts.

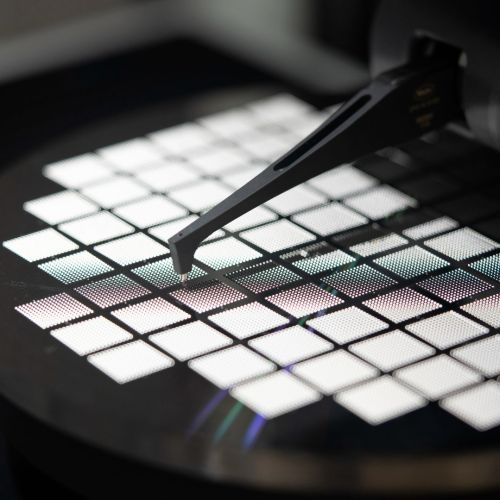

The company started in a garage in 2013 based on a problem solved by its founder, Marc Wielandts, during his free time. This idea led to the development of a unique patented technology called DPI® (Dynamic Part Indexing) that is a real breakthrough solution for the machining of lens arrays and monolithic multi-cavity optical molds.

Using this technology, Wielandts UPMT manufactures lens array masters to customer specifications for diverse applications: MLA masters for automotive lighting, fully populated masters for nano-imprint replication processes, IR lens batch machining and optics at wafer level.

To further provide solutions to its customers, the company also developed custom replication technologies to produce polymer optics. While manufacturing its own replication tooling, the company provides replication services from prototyping to volume production for MLA parts or challenging optics. These replicated optics are particularly suited to new demanding applications like LiDAR, consumer goods diffusers, imaging MLAs, AR/VR pancake lenses, …

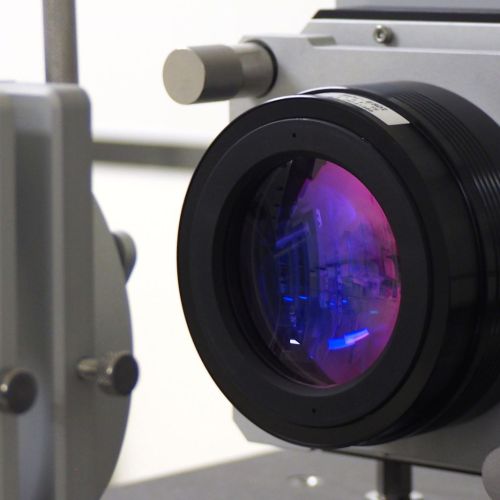

Based on its State-of-the-Art equipment (ultra-precision turning lathes, metrology equipment, CNC milling,…) and the experience of its employees, the company also provides ultra-precision machining services to various markets: space, defence, IR, …

Still 100% family owned, the company’s day to day business is now managed by the second generation with focus on continuous development, both at personal level for each of the highly skilled employees as at technological level, in order to provide to its customers unique and appropriate manufacturing solutions.

Interview of Wielandts UPMT’s founder