We provide solutions for the following applications:

Contact usWho we are

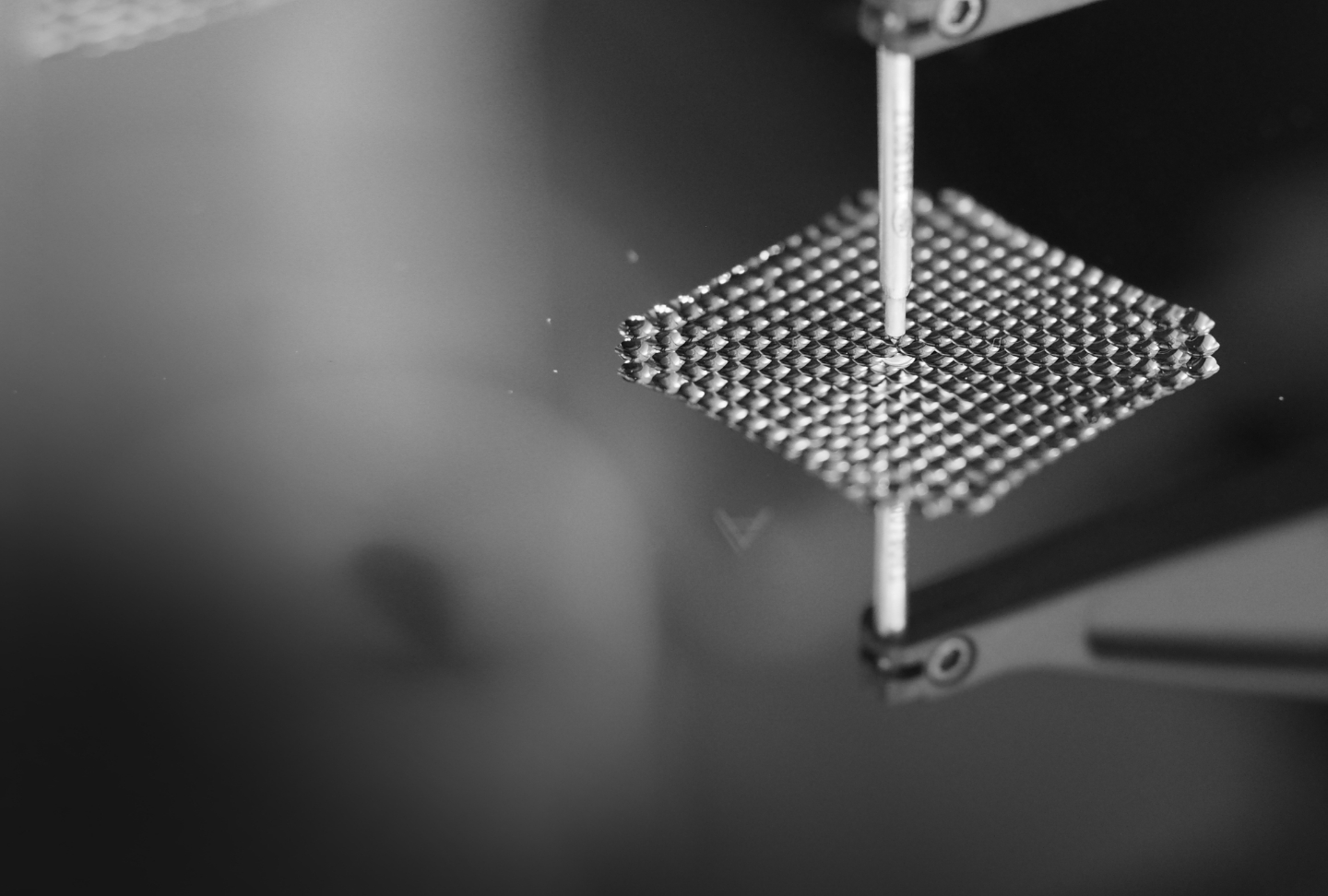

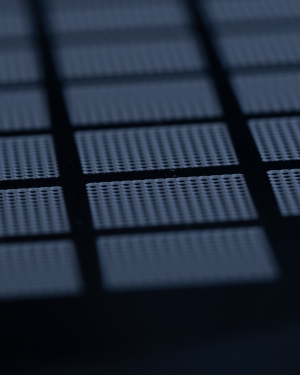

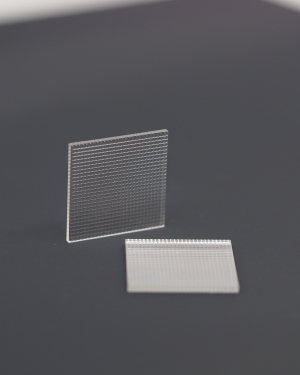

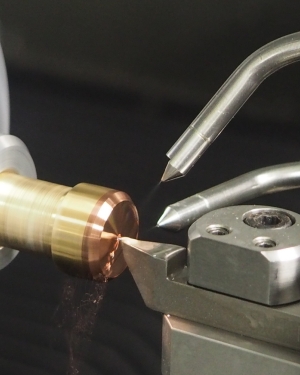

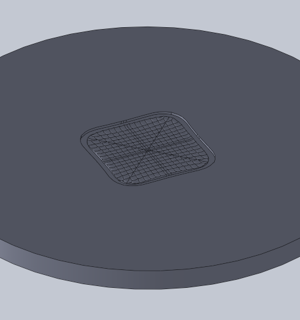

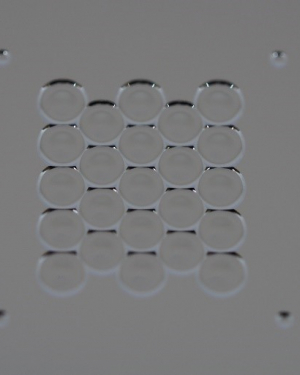

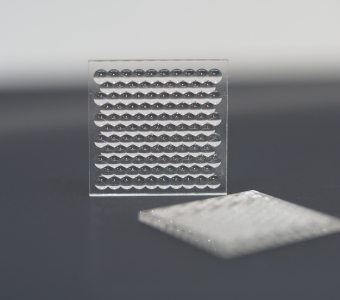

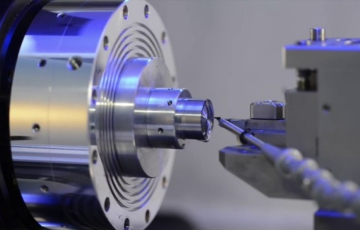

Unique ultra precision machining and replication technologies for your next generation products

Wielandts UPMT is a technological company that develops unique machining and replication processes to provide custom solutions to the most demanding customer requests for optical and mechanical precision parts.

What we do

Ultraprecision technologies for your application

News

Jobs

Work in an exciting technological environment

Our success lies in the people we recruit. In order to continue our development, we are constantly looking for new talents willing to join us.

Contact us

Can’t find what you are looking for?

Or any question about our work and capabilities?

Our teams are there to help.

Send us your request and we will be happy to answer you.