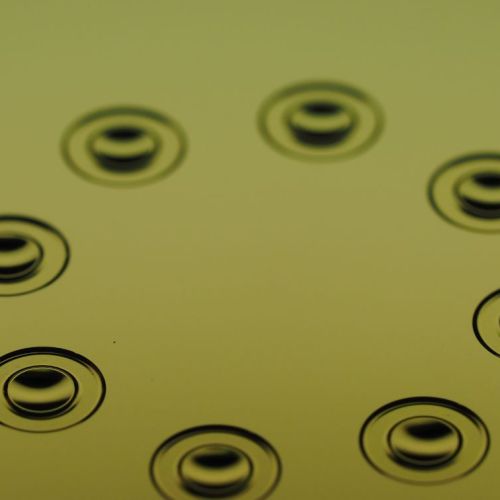

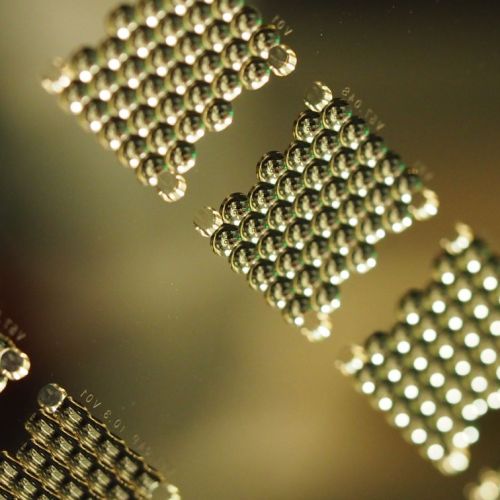

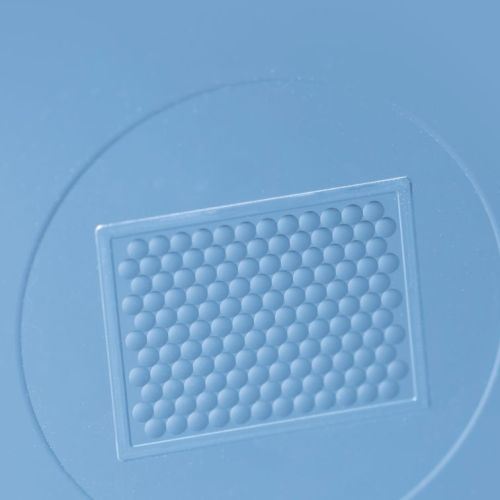

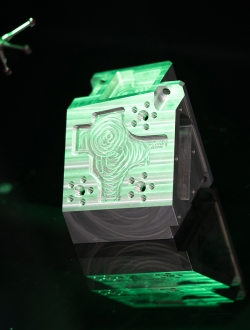

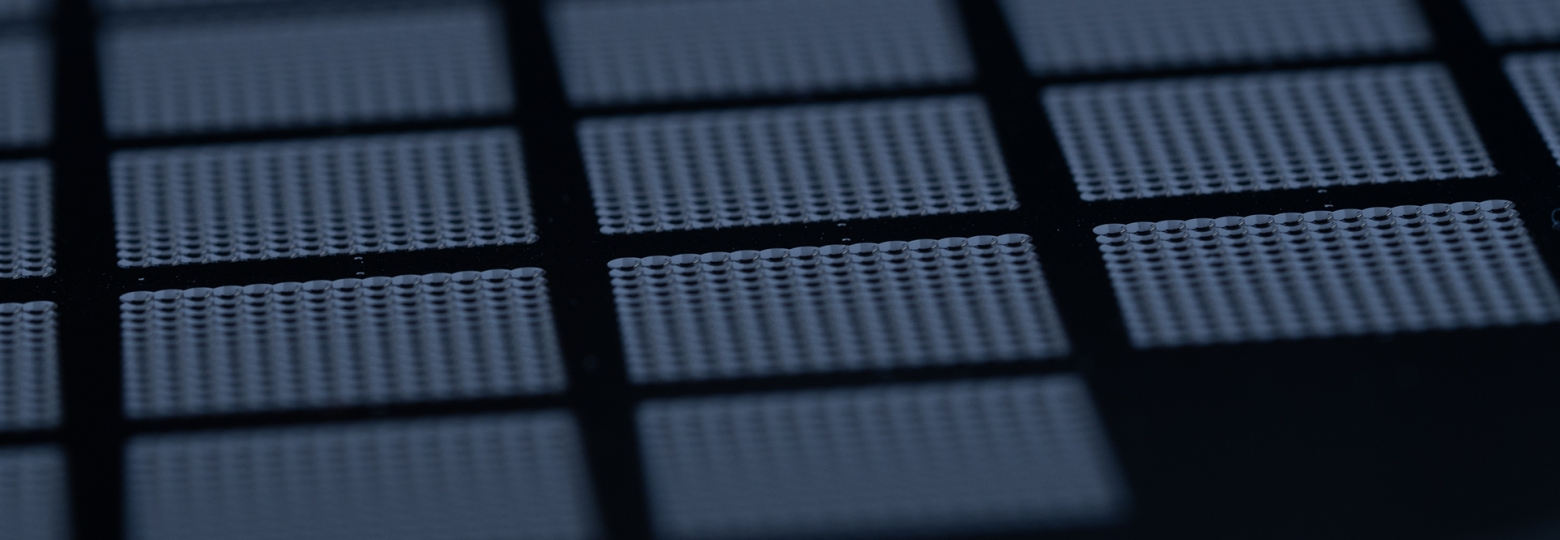

DPI® brings many advantages compared to classical freeform machining techniques like amongst others: lower surface form error, reduced machining times, increased geometrical freedom, true 100% fill factor (with extremely sharp edges between intersecting lenses), lower surface roughness, etc, which makes DPI® a unique solution for your next lens array application.

Masters have been successfully manufactured for a broad range of customers’ applications like: polymer-on-glass replication for automotive illumination, lens arrays for augmented- and virtual reality, consumer goods sensors and imaging devices, medical applications, etc.

DPI® provides the same ultra-precise quality for all lenses in a fully populated master, simplifying your replication processes and improving their productivity.

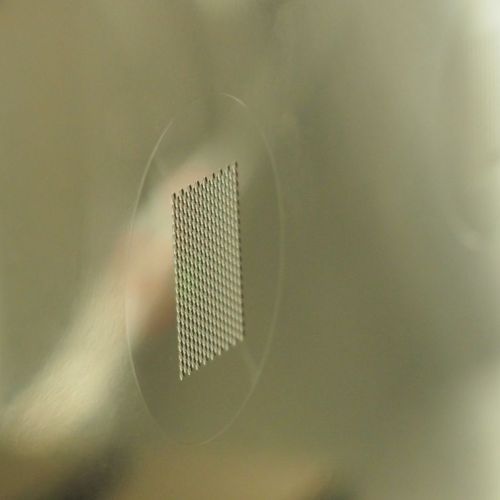

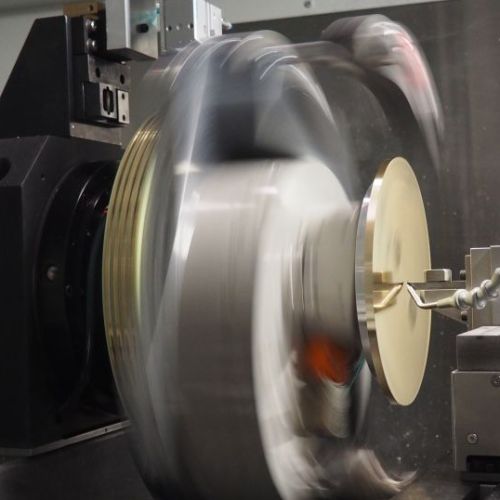

| Diamond on-axis turning | |

| Shapes | Aspheres, mild freeforms, each lens can have a different optical definition |

| Feature size | > 10 µm |

| Lens sag | > 10 µm, < 10 mm |

|

Form irregularity |

100 nm p-V |

| Ra roughness | 2 nm |

| Edge slopes | 80°, limited by tool clearance |

| 100% Fill factor | Yes |

| Position accuracy | Lens to lens: < 1 µm MLA to MLA: < 1 µm |

| Diffractive structure | Yes (axis symmetric) |

| Master size | Up to 8" |

| Number of lenses | Up to tens of thousands |

| Master material | NiP, brass, PMMA, CuBe, ... |