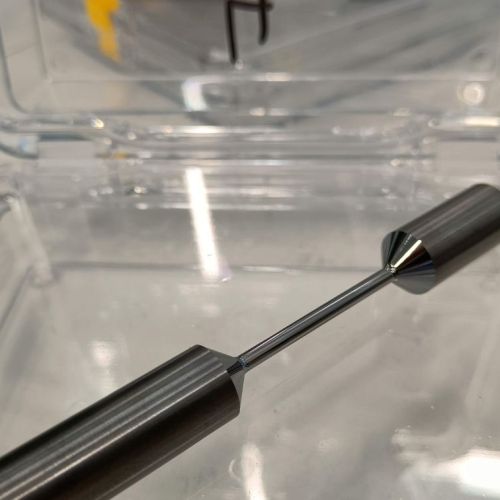

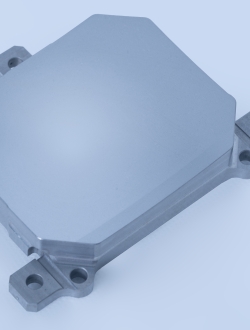

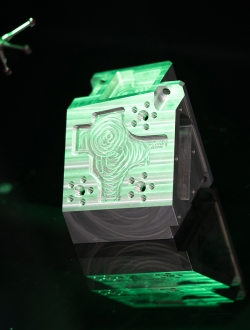

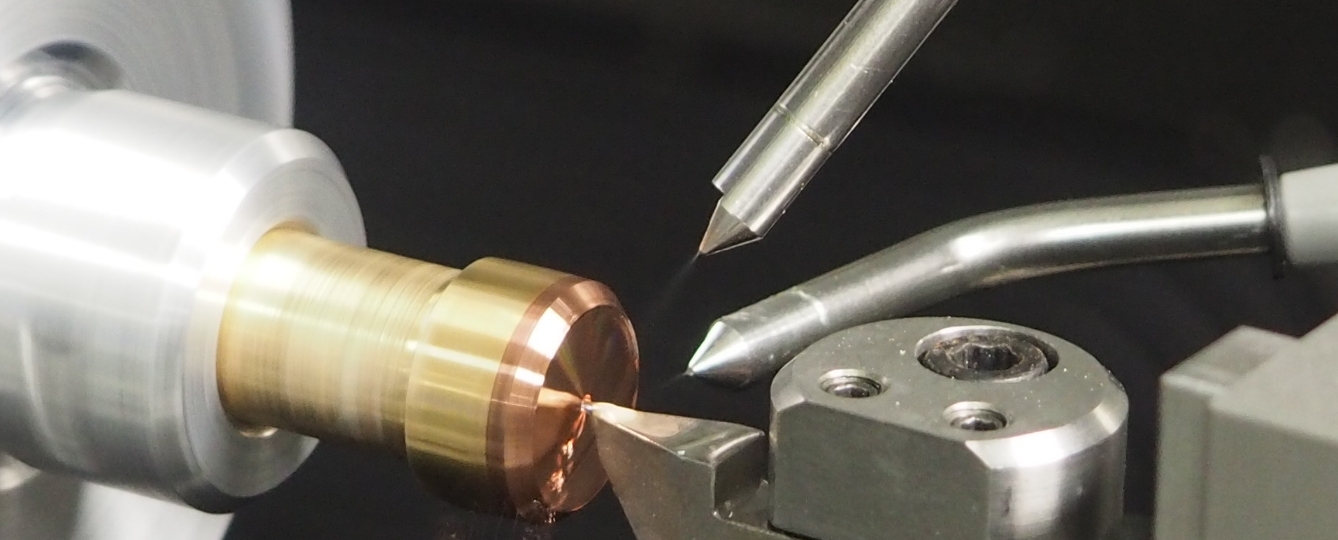

Wielandts UPMT provides a complete manufacturing service, from engineering and design support to material procurement from reliable providers, CNC machining, heat treatment, diamond machining, surface treatments and coatings and metrology. By performing activities internally, such as CNC machining, the company ensures best lead times while directly controlling the quality of the manufactured parts.

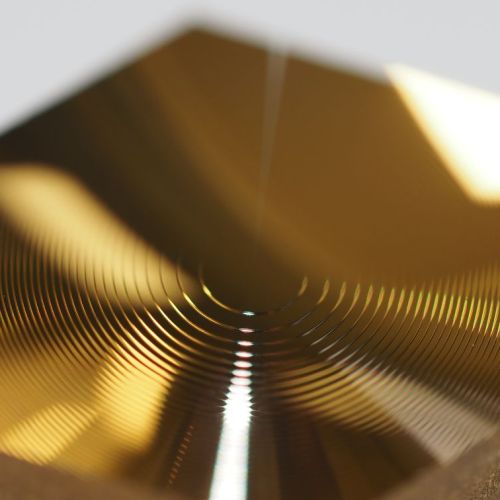

Thanks to its extended experience, Wielandts UPMT’s teams are used to combine different techniques for machining, fixturing and compensation, putting the machines in many different setups when required. For example, equipped with a fast-tool-servo, the machining various types of freeform optics can be done in the most efficient way.

With these technologies and its highly skilled staff, Wielandts UPMT supports multiple activities and applications like mirrors for space instrumentation, observation, laser and UV opitcs, prototype imaging and illumination lenses, ZnSe infrared lenses, gratings, ultraprecision research mechanical parts, etc.

| Single Point Diamond Turning Services | |

| Materials | Copper, copper beryllium, brass, aluminium, nickel-phosphor, germanium, zinc selenide, zinc sulfide, calcium fluoride, PMMA, polycarbonate, ... |

| Geometries | Spherical, Aspherical, off-axis parabola, toric, ellipsoid, fresnel, diffractive, freeforms |

| Size | 1-450 mm diameter |

| Form irregularity | 100 nm p.-v. |

| Ra roughness | 2 nm |

| Dimensional accuracy | 100% |

| Industries | Consumer, aerospace, OEMs, defense, medical, ... |