Different replication technologies have been developed in house, either based on injection molding or compression molding processes. Depending on customer’s requirements, these processes can be adapted to produce parts with highest quality.

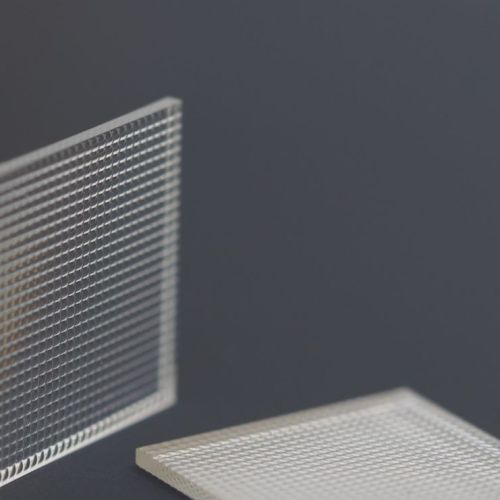

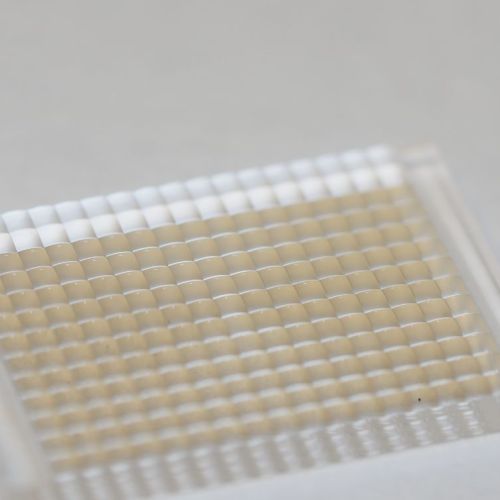

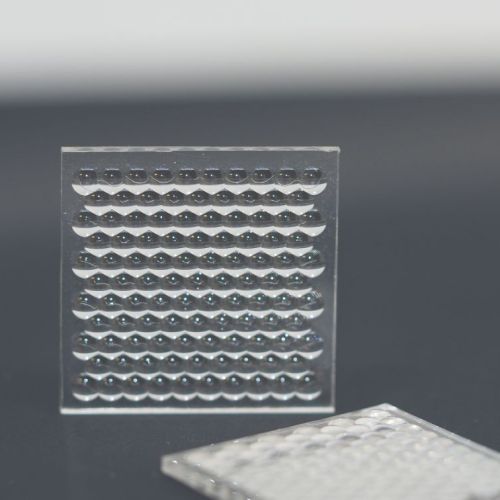

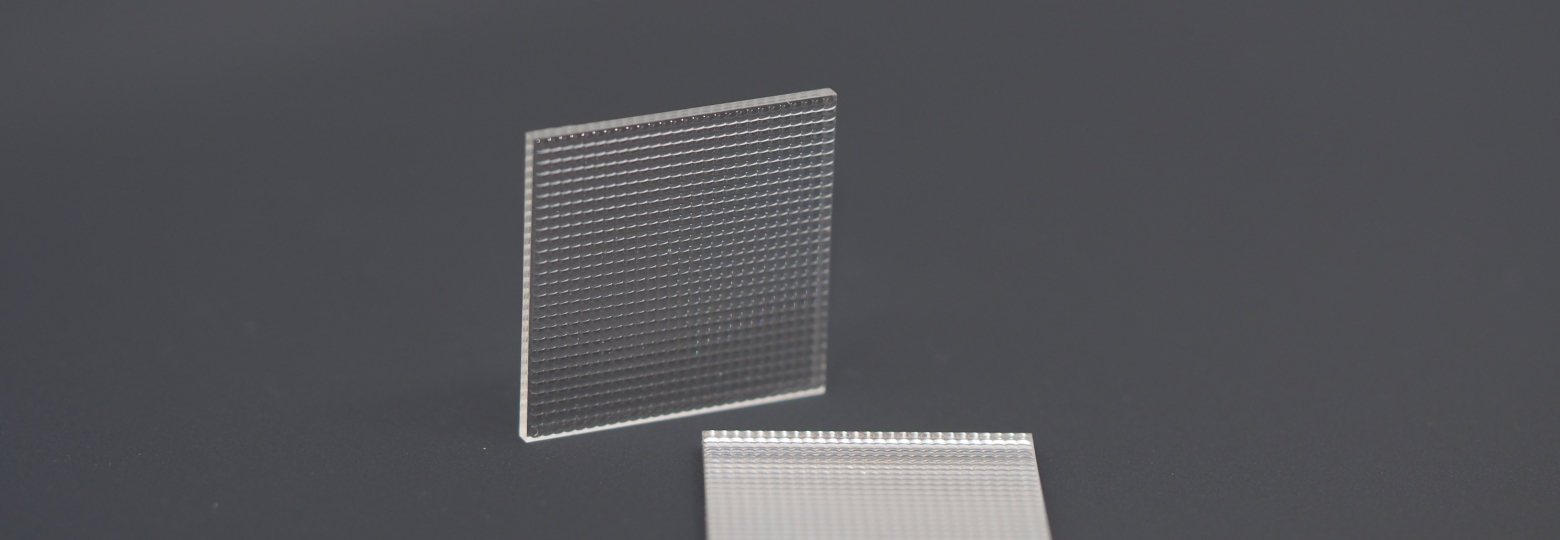

Based on a specially adapted injection molding process, Wielandts UPMT has developed a replication technology to produce polymer lens arrays on a wafer level. Using a DPI® master, lenses and arrays can be replicated in a highly productive way, which makes it perfectly suitable for high volume applications. Wafers containing multiple elements can subsequently be handled, coated and diced. This technology has been used to produce lens arrays of all kinds, such as beam homogenizers (fly’s eye MLA), LiDAR arrays, beam shaping, or even imaging lens arrays.

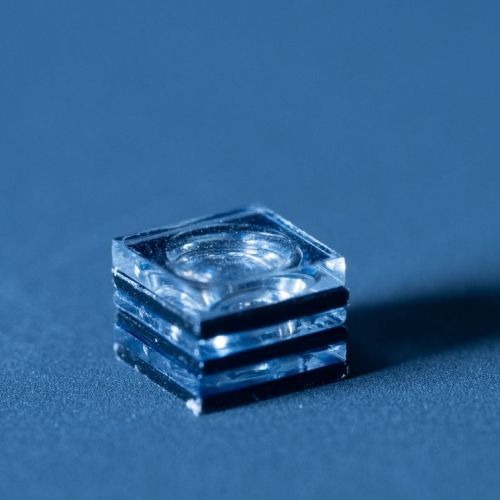

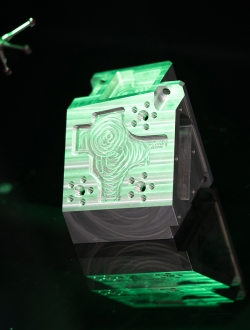

For lenses showing extreme design requirements, a high precision compression molding process has been developed by Wielandts UPMT, called HiFi Optics®. This process is an isothermal molding technology designed to bring the lenses to their final shape with outstanding accuracy. By compressing the lenses in a closed-cavity cycle, small features are replicated with high fidelity while allowing particularly low minimum thickness across the part, high aspect ratio, very high slopes and low birefringence. For example, this process has been used to produce large pancake lenses, or very tiny freeform collimation lenses for augmented reality applications.

| MLA Molding | |

| SFE | Down to 300 nm p-v |

| Ra roughness | < 10 nm |

| Thickness | 0.6 - 3 mm |

| Max slope | < 40° |

| Fill factor | 100% |

| Double sided | Yes |

| Shapes | Aspheres, diffractives, freeforms |

| Materials | Optical thermoplastic materials : PMMA, PC, COC, COP |

| HiFi Optics® molding | |

| Form irregularity | Down to 150 nm p-v |

| Ra roughness | < 5 nm |

| Position accuracy | Optical surfaces co-alignement : 1-2 µm |

| Minimum thickness | < 200 µm |

| Aspect ratio | >5 |

| Max slope | Up to 75° |

| Birefringence | Down to 10nm/cm |

| Shapes | Aspheres, diffractives, freeforms |

| Materials |

PMMA, PC (Mitsubishi EP Series, ...), COC (Mitsui APEL), COP (Zeonex) |